Flooring Answers: One Step at a Time – Specifiers’ Guide to Resilient Stair Treads

Resilient stair treads are a tough, durable, and safe covering for stairs from heavy duty to light usage. There are two types (rubber and vinyl), two shapes (round nose or square nose), two different constructions (one piece tread and riser or separate tread and riser), and a variety of surface textures. There are variations in installation guidelines among the different manufacturers, but here are some general guidelines.

PREPARATION

Make sure treads are stored flat; acclimate materials and adhesive on site for two days at 65o – 80o. Substrate must be clean, flat, and smooth; prepare according to the tread manufacturer’s instructions.

Make sure treads are stored flat; acclimate materials and adhesive on site for two days at 65o – 80o. Substrate must be clean, flat, and smooth; prepare according to the tread manufacturer’s instructions.

The most important part of the preparation is the nose – the very edge of the step where feet hit as people are walking. If this edge is damaged or wavy, this will be a point of weakness that will cause the tread to crack and might cause someone to trip. Epoxy nose filler takes care of minor irregularities, but any major damage needs to be fixed before the treads are installed.

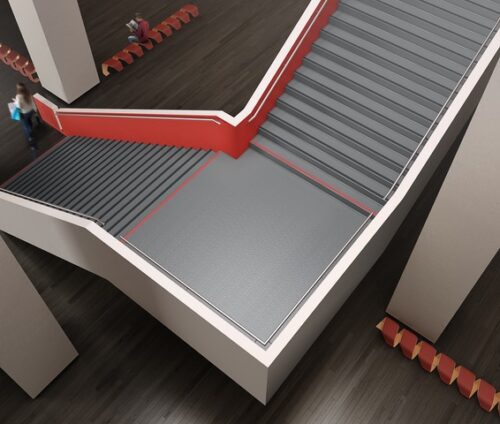

The treads can either be the traditional tread, with a separate riser, or the one-piece tread and riser that provides a clean, seamless installation. The one piece is best installed with a“cove stick”at the back of the step where the tread meets the riser – just like“flash cove”sheet floors. Visually, this creates an even curve at the juncture of step and riser and because the cove stick fills the empty space at that corner, the tread is much less likely to crack during use.

ADHESIVES

Because there are different formulations of stair treads, use the adhesive that is specified by the manufacturer. Another option is a tape system that many manufacturers are now using that allows for almost immediate traffic on the steps.

Because there are different formulations of stair treads, use the adhesive that is specified by the manufacturer. Another option is a tape system that many manufacturers are now using that allows for almost immediate traffic on the steps.

One of the unique parts of stair tread installation is the use of epoxy nose filler, also called nose caulk. This is not used to adhere the treads, but is filler used to fill in voids between the edge of the step and the nose of the tread. This two-part epoxy sets“hard as a rock,”providing a strong bonding support under the nose, eliminating movement that leads to the tread cracking. Some stair tread manufacturers do not require epoxy nose filler, but I’m a bit old school in this regard, I feel better knowing that bead of epoxy is there so that the installation is solid as a rock.

FINISHING

Some manufacturers have a matching color acrylic caulk available that can be a nice way to fill any gaps in a stair tread installation.

At the top step or a landing, careful attention needs to be paid to what the floor covering will be on the landing or corridor that the stairway leads to. Don’t assume the top step will be just another stair tread. Sometimes it is better to use a heavy-duty rubber nosing on that top step, especially if it will meet another resilient floor. If the landing and the treads will be matching, then the top tread must be trimmed correctly to match the pattern up with the landing. Some treads have a trim mark on the back so the installer can make this cut easily.

Stringers are sometimes used on stair tread installations for a matching look on the side of the steps. This takes careful trimming and is best done by making a pattern of cardboard that can then be transferred onto the stringer material.

After installation, protection is critical! It’s important to keep traffic off the stairwell for the recommended time. If the job was done with adhesive, the treads can shift is someone starts walking on the steps too soon after installation.

SPEC DETAILS

When writing the specification for stair treads, be sure to get the part numbers right. With the wide choice of textures, profiles and colors, some products have many options and I have seen the wrong product delivered because of a missed number. When in doubt, check in with your rep for help. Also, always put your rep’s name and contact info on the finish schedule. Otherwise, it may take the flooring contractors extra time to find out who to call for pricing.

When writing the specification for stair treads, be sure to get the part numbers right. With the wide choice of textures, profiles and colors, some products have many options and I have seen the wrong product delivered because of a missed number. When in doubt, check in with your rep for help. Also, always put your rep’s name and contact info on the finish schedule. Otherwise, it may take the flooring contractors extra time to find out who to call for pricing.

Although resilient stair tread installation requires a lot of detail work, it’s not that difficult once you get the hang of it. With more and more treads being sold for safety and aesthetic reasons it’s an increasingly important component of the design process.

Explore all our Flooring Answer Articles

Explore all our Flooring Answer Videos

ABOUT CHRISTOPHER

Christopher Capobianco covers the NY Metro and Connecticut area for Spartan. He’s a fourth-generation floor coverer whose family has been in the business since the 1930s. For 36 of the last 43 years, he’s had roles in retail, distributor, and manufacturer sales. The other seven years were spent in floor covering training and technical support. He also has been a part time columnist for various flooring magazines since 1988 and is a long-time member of the ASTM Committee on resilient flooring. You can reach him here.